CNC Machining Services

overview

What are precision machining services?

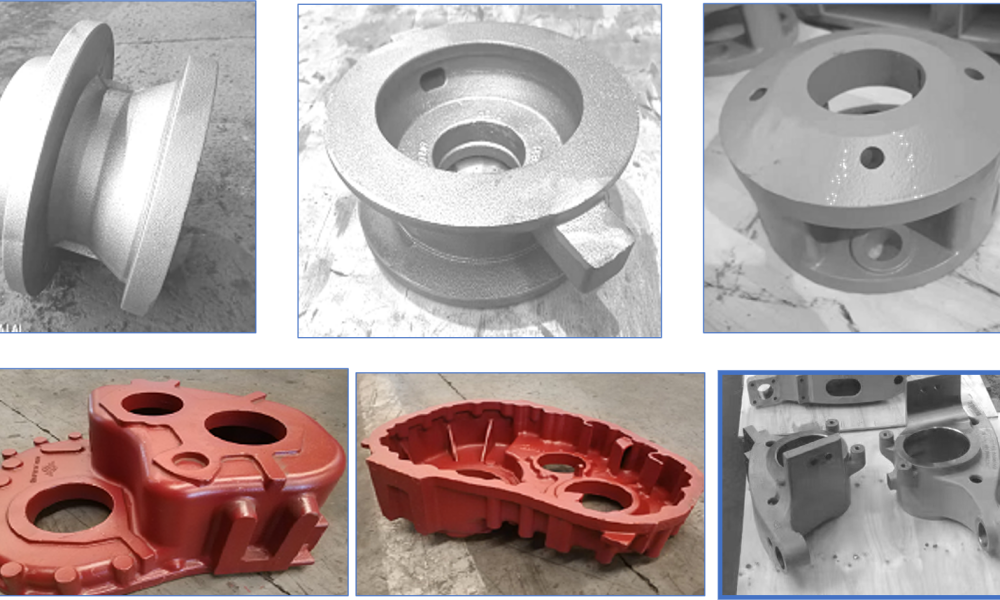

NIG’s Machining Services provide specialized outsourcing for your manufacturing needs. Leveraging cutting-edge CNC technology, we deliver precise, high-quality parts while expertly managing and optimizing every step of the production process.

We offer high-precision CNC metal processing based on your drawings or samples, delivering customized prototypes and products. Our services include CNC turning, milling, grinding, electrical discharge machining, wire EDM, laser engraving, and more. We work with a range of materials, including stainless steel, titanium alloys, aluminum alloys, and zirconium, and are equipped to handle all types of surface treatments.

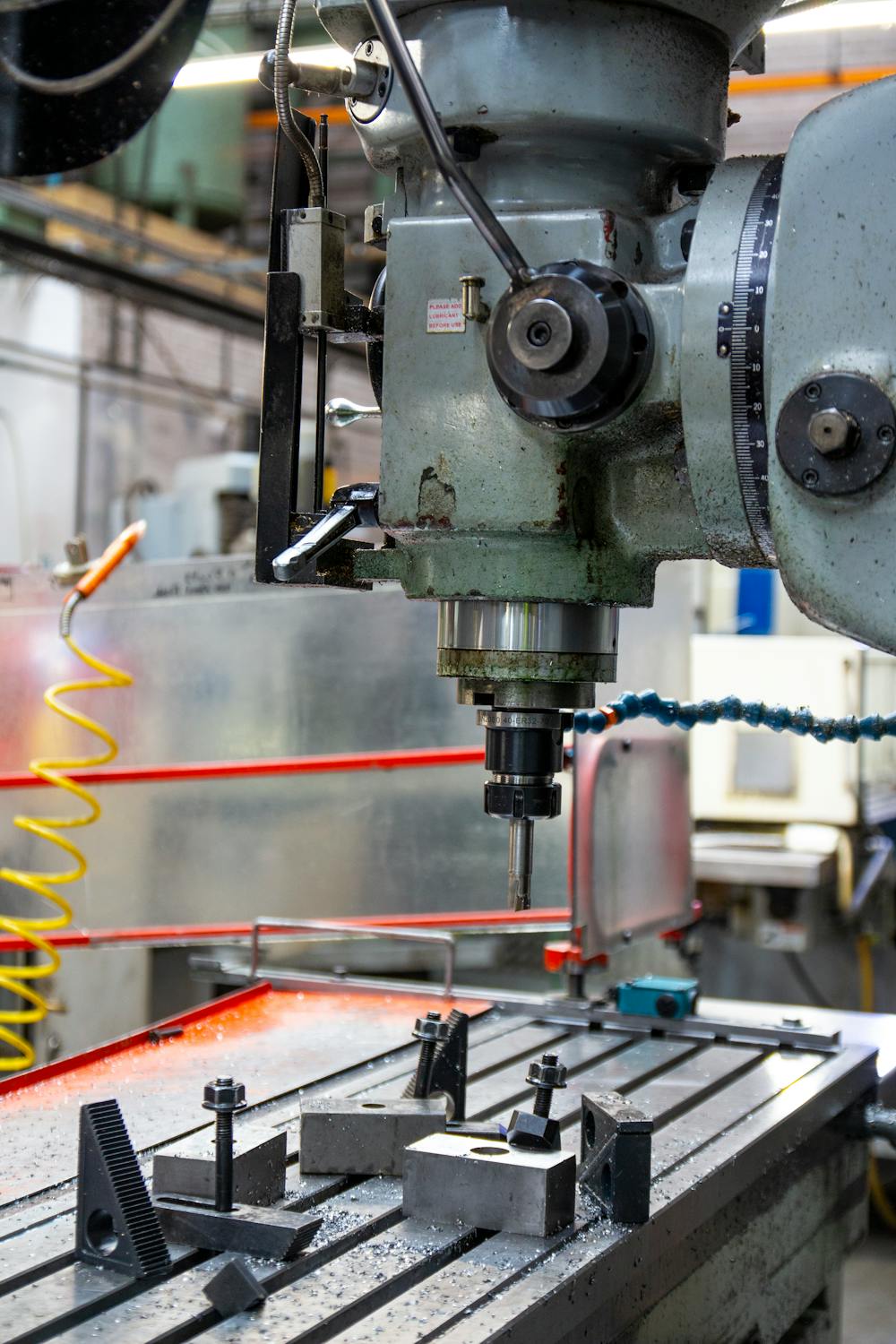

- 3-axis and 4-axis Milling

- 2-axis Turning

- Wire-cutting and Die-sinking (EDM)

We handle a wide range of post-processing tasks, from surface finishing to assembly. Our aim is to offer comprehensive, integrated manufacturing services that minimize overhead costs while enhancing quality control and reducing lead times.

- Anodizing

- Alodine Coating

- Powder Coating and Spray Painting

- Plating

- Heat Treatment

(outsourcing to outside partners.)

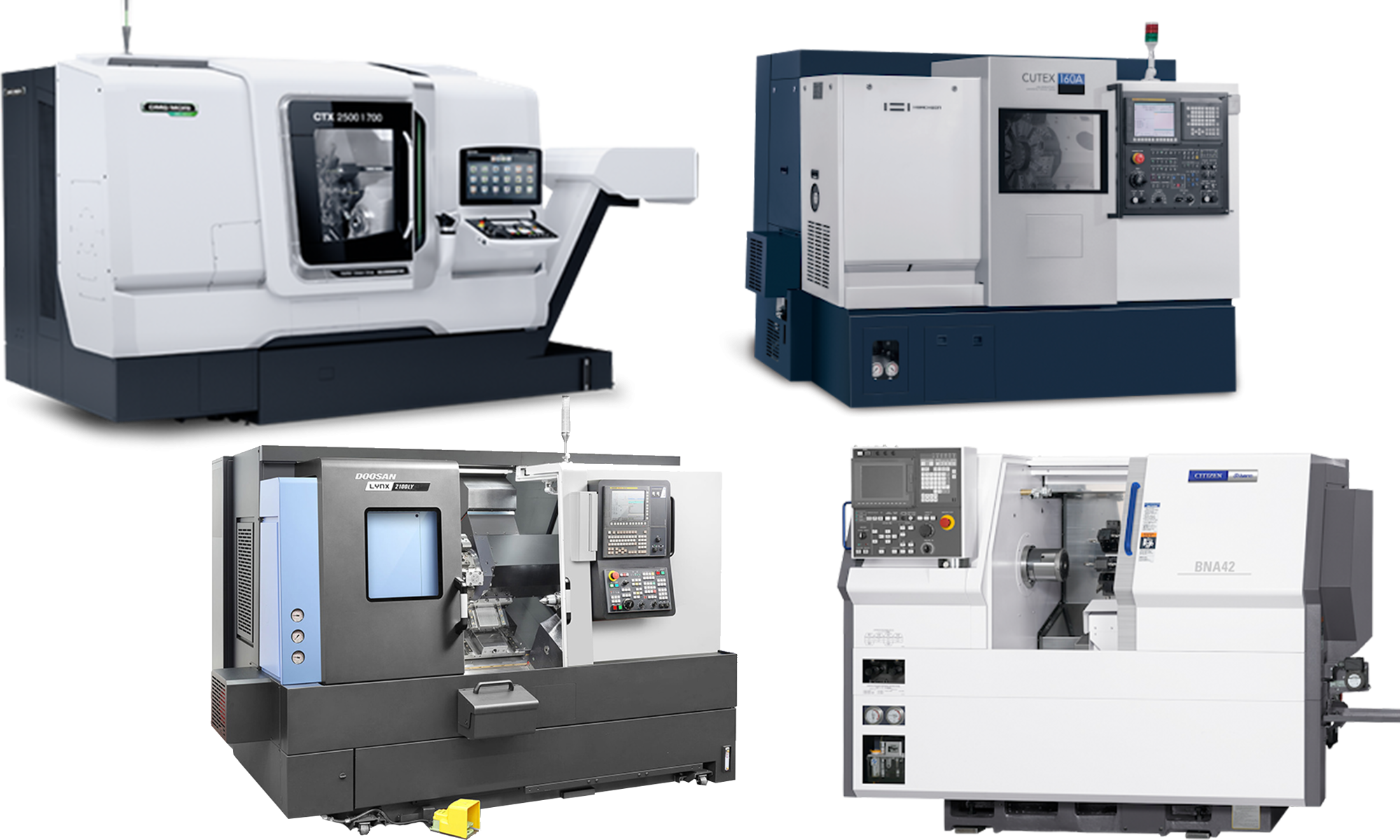

Manufacture Capacity

Equipped with a wide range of machining units, including horizontal, vertical, and CNC machining centers, as well as a dedicated 3D printing center, we excel in providing tailored, high-precision processing solutions.

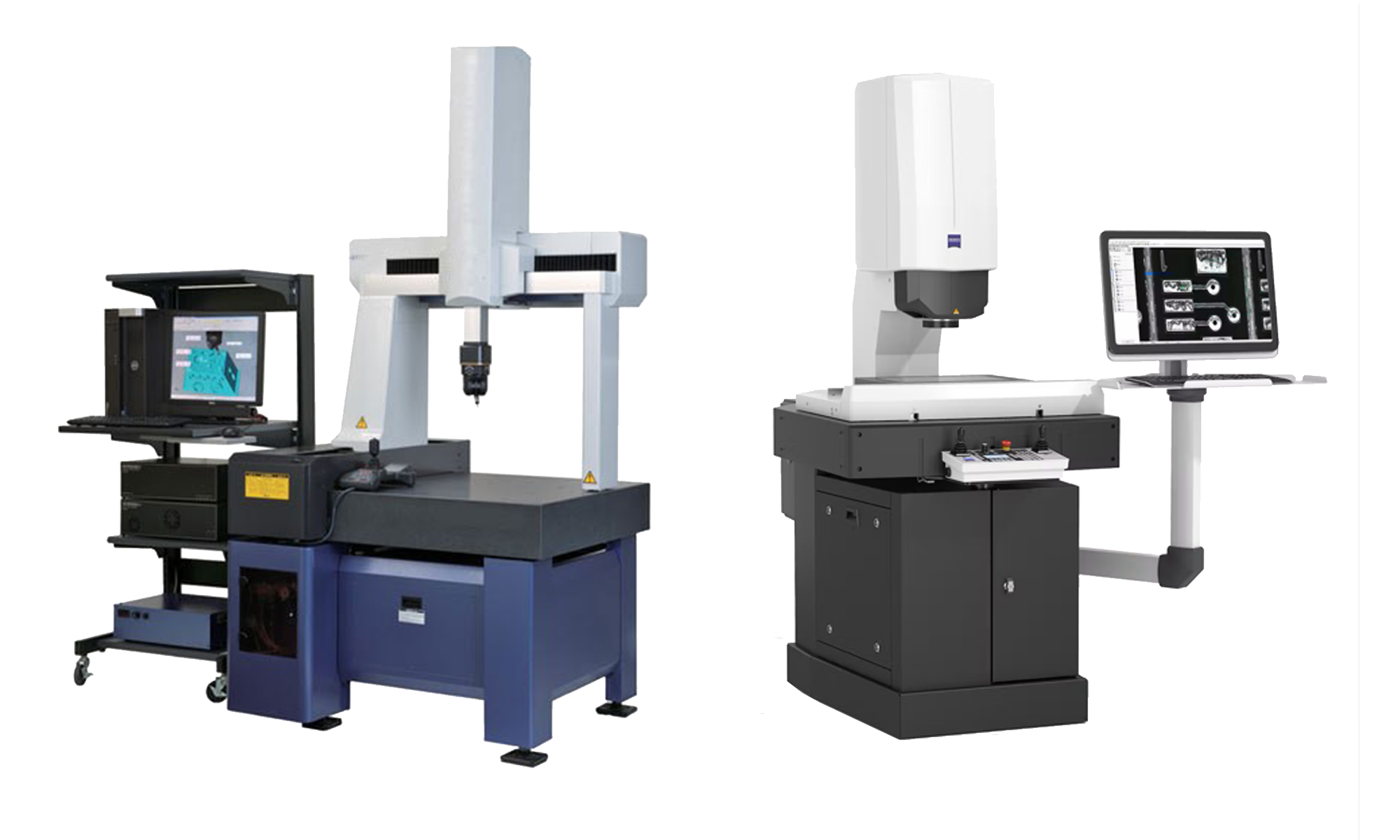

Our machining capabilities are designed to handle a wide range of manufacturing requirements with exceptional precision and versatility

Part Sizes and Tolerances

Materials

We source and import materials that meet ASTM, JIS, DIN, and GB standards. Our selection includes a full range of common engineering metals and plastics.

Additionally, we collaborate closely with trusted local suppliers to source high-quality preform materials.

We can provide material certificates and inspection reports upon request. To ensure availability, please request this information in advance, as obtaining material certificates retrospectively may be challenging.