We are a premier provider of Integrated Engineering, Industrial Automation, and Digital Transformation solutions.

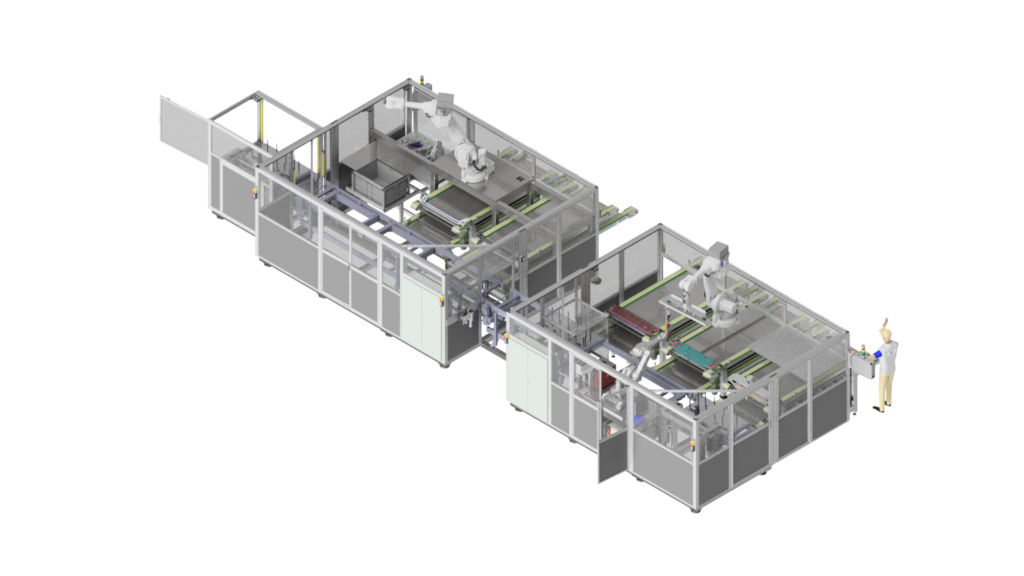

As a one-stop solution provider, we combine expertise in mechanical product design, electronics, embedded systems, software development, testing, and manufacturing engineering. Our offerings also include a comprehensive portfolio of Industrial Automation and Robotics products and solutions.