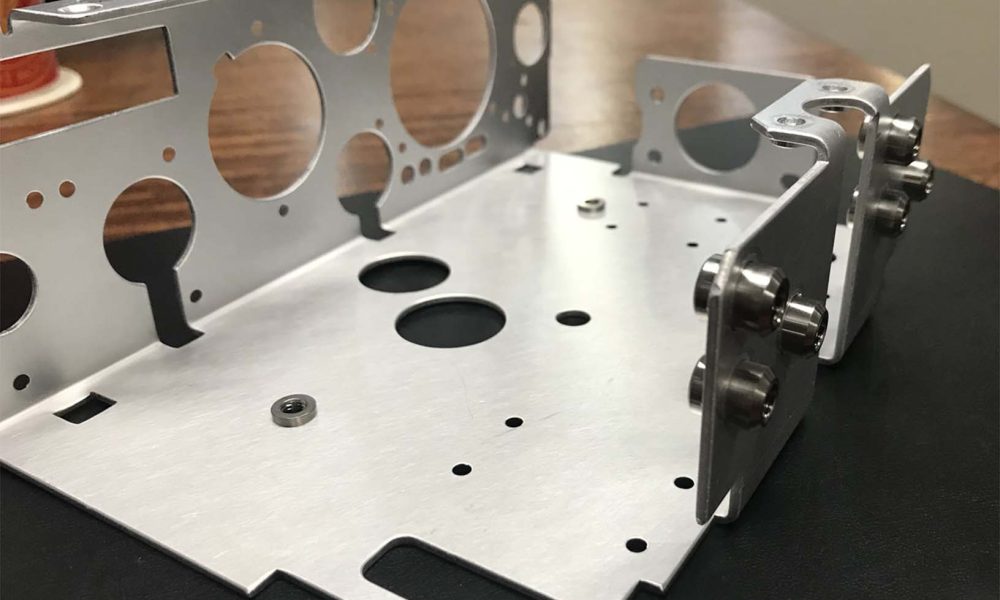

Sheet Metal Fabrication

overview

What is Sheet Metal Forming services?

We are dedicated to providing end-to-end manufacturing solutions with an emphasis on precision, quality, and efficiency. Our expertise spans sheet metal fabrication, welding, and surface finishing, enabling us to manage projects of all sizes—from single components to fully assembled product designs. As a reliable partner, we pride ourselves on delivering solutions that align with your exact requirements while upholding the highest standards of craftsmanship and attention to detail.

Our Main Capabilities:

- Fiber Laser Cutting Machine: Delivers precise, high-speed cutting for various materials, ensuring clean edges and minimal waste.

- Press Brake Machine: Facilitates accurate metal bending, ideal for producing components with complex geometries.

- Turret Punch Press Machine: Provides efficient and versatile punching solutions for creating intricate patterns and forms.

- Fiber Laser Welding Machine: Ensures strong, clean welds with superior precision for a variety of applications.

Advanced Surface Finishing Services:

- Powder Coating and Spray Painting: Durable and visually appealing finishes that enhance both aesthetics and corrosion resistance.

- Anodizing and Alodine Coating: Specialized treatments to improve surface hardness, corrosion resistance, and conductivity.

- Silk Screen Printing: High-quality graphic printing for branding, labeling, and decorative purposes.

At NIG, our modern equipment and skilled team make it easy to handle complex manufacturing needs. We provide solutions tailored to your requirements, from small custom orders to large production runs. With advanced technology and a focus on quality, we ensure your projects are delivered on time, on budget, and to your satisfaction.

Equipment and Capabilities

Materials

We source and import materials that comply with ASTM, JIS, and DIN standards, ensuring high quality and reliability. Our range includes:

This diverse selection of engineering-grade materials enables us to meet a wide variety of manufacturing requirements.

We can provide material certificates and inspection reports upon request. To ensure availability, please request this information in advance, as obtaining material certificates retrospectively may be challenging.