Precision injection molding tools crafted in Vietnam, ensuring durability and accuracy.

NIG supplies

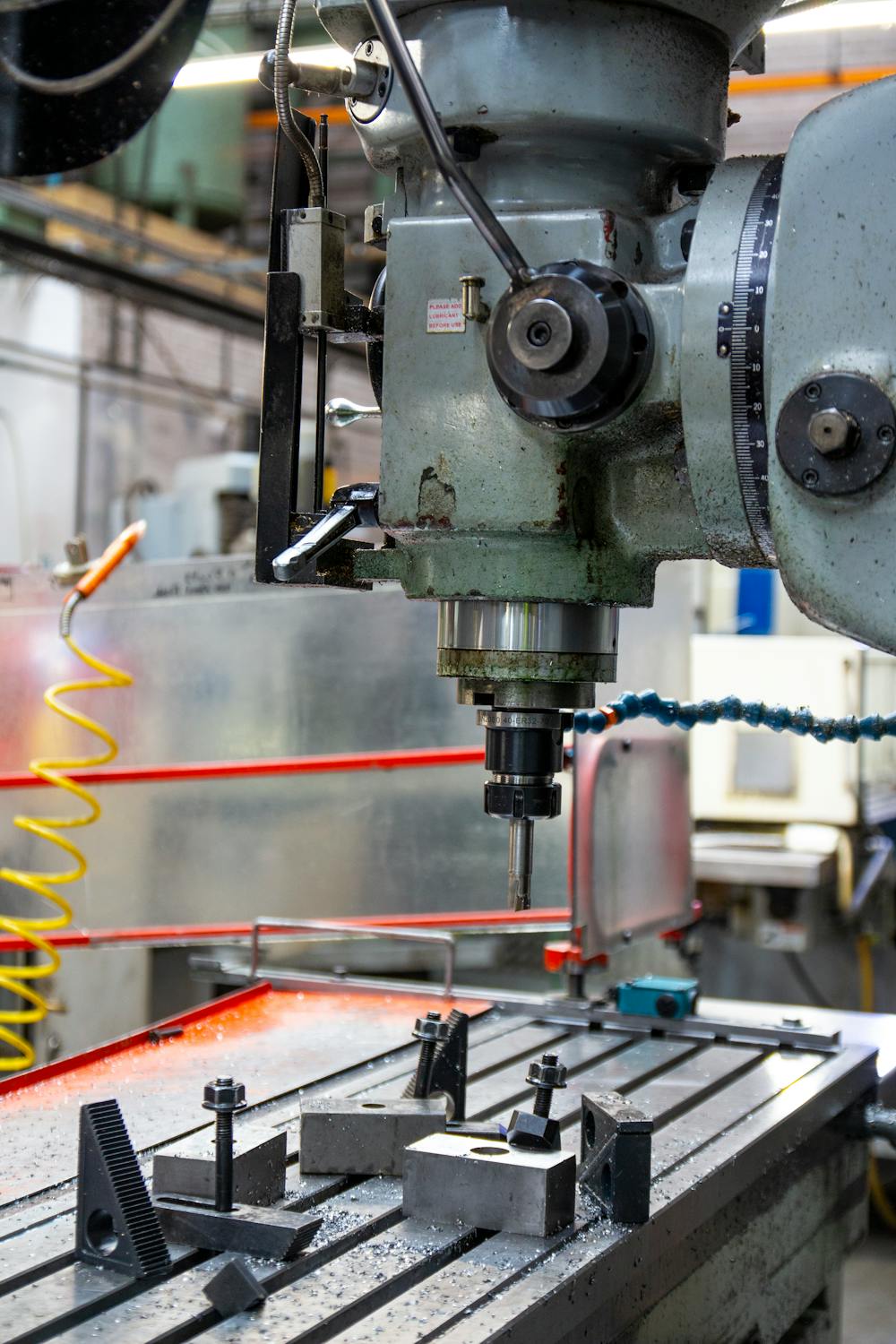

Mold Fabrication

Mold Materials

We utilize a range of premium materials for mold tooling, including P20, HPM7, PAC500, FDAC, SS420, NAK80, Nimax, SKD61, S-Star, Stavax, Beryllium Copper, W360(1.2355-S7), and DHA-2(1.2344-H13), with occasional use of A7075 for specific applications.

Sizes and Features